Valentine: “It is rare to find watches with transparent caseback showing a decorated mechanical movement”.

Marc: “What a pity it is to not display the finesse and diversity of the watchmaking finishes.”

V. “Only the biggest watchmaking brands take the time and the means to work on the decoration of movements. It is simply pure aesthetics and emotion!”

M. “What if there was a watchmaking object revealing these magnificent finishes and decorations to everyone?”

It all began with this question, during a discussion between two friends, entrepreneurs during the day and watchmaking enthusiasts the rest of the time.

The idea was born on the terrace of a Parisian café, the Baroche, located in the 8th arrondissement of Paris.

The movements are, most often, hidden on the back of the watch or even worse, hidden by a solid back. Our passion for the most beautiful watch movements has given us the desire to highlight watch decoration.

This is how the project to create a totally unique object, symbolizing a fine watchmaking movement, was born, while sitting on the terrace of our Parisian café. After many tests, the first sketch of Ébauche 01 was drawn.

After this first sketch, the idea of creating more than a simple object was born.

From the very beginning we wanted to build a watchmaking entity that does not make watches but rather “watchmaking objects”.

For every watch collector, amateur or expert, as well as for every watch enthusiast, there is a clue to start a conversation about this passion.

The brand name INDICE comes from this observation. For us, this clue takes today the appearance of a watch object: Ébauche 01.

Lovers of artisanal brands, we wish to respect as best as possible the watchmaking tradition that has lasted for decades thanks to the craftsmen.

Understanding the past and getting to know it is the best way to create a unique watchmaking object!

Our desire was to make a totally unique watchmaking object, never seen before. This one was made in the same way as a mechanical movement. In fact, it is easy to imagine that part of a movement was extracted for the creation of Ébauche 01!

Just like a watch case, we have formed a slight curve to perfectly fit the shape of the wrist.

Watch movements are most often made of brass or nickel silver. We could not work with these materials. While in contact with the skin they can oxidize and age prematurely.

We therefore naturally chose 316L steel. This is mainly used for the manufacture of watch cases. The 316L steel is at the same time very qualitative, durable, stainless, it is used as well in aeronautics as in the advanced medical instruments.

In order to eliminate the rough aspect of 316L steel, we decided to work with the most beautiful of watchmaking finishes: Côtes de Genève.

These are observed only in the decoration of top-of-the-range movements. They require very specific skills and are mastered only by a few companies and craftsmen. Côtes de Genève captures light and reflections in a unique way and gives Ébauche 01 an instantly recognizable look.

To make this watchmaking object even more visual, we decided to add a screw that is blued by a heating technique. In an oven, the screw will go through different temperatures until it is “oxidized” on the blue surface, thus capturing the eye with its amazing deep blue. This screw has a “polie bloquée” head which makes its appearance even more brilliant. This type of screw is rare, even in the most beautiful mechanical movements. This piece is made in Switzerland in the town of Le Chenit.

In Switzerland, there are hundreds of brands of Swiss Made watches. The competition is tough and manufacturing in countries other than Switzerland is often preferred to optimize costs.

The objective of manufacturers is to increase margins while reducing the quantity of parts manufactured in Switzerland, often at the expense of quality.

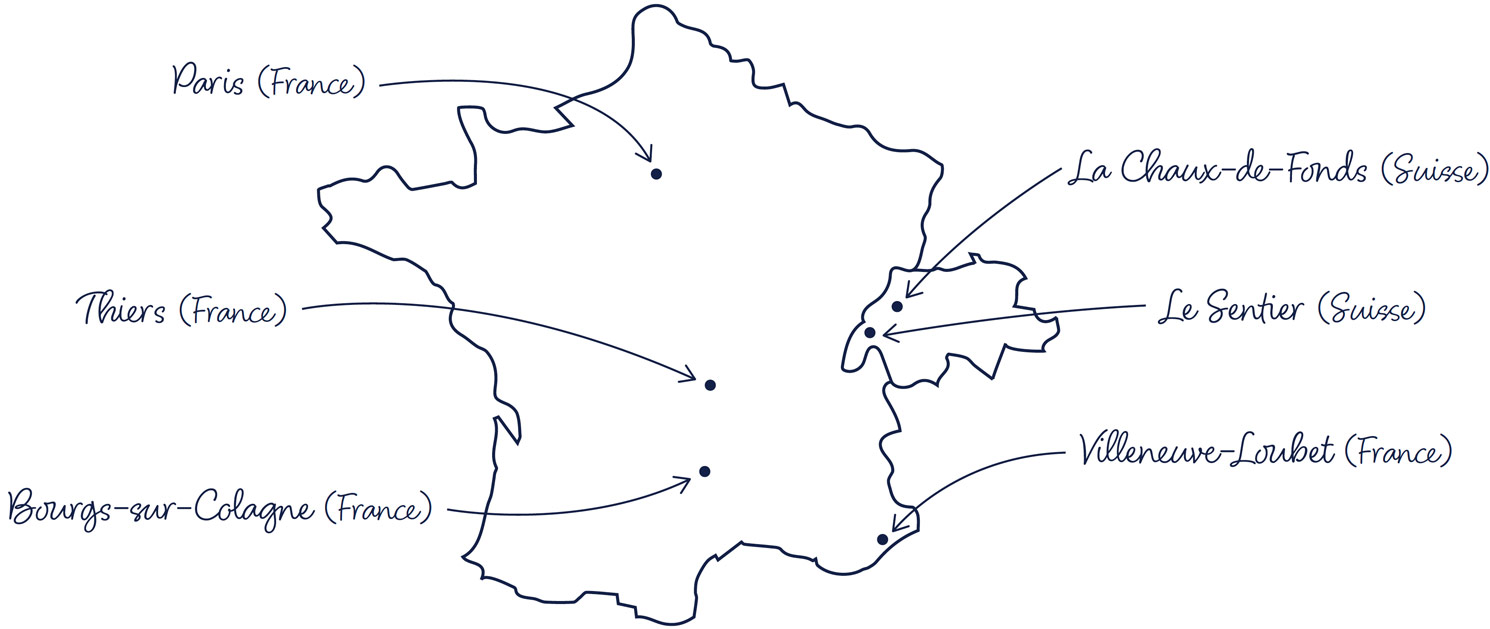

In total contradiction with this approach, we voluntarily choose to work with French and Swiss companies and craftsmen in order to create a superior quality, purely Franco-Swiss product.

Our goal is to keep the know-how in France and Switzerland as much as possible.

The 316L steel is totally transformed and machined in France in the Auvergne-Rhône-Alpes region. The partner family workshop in charge of it is on a human scale and has specific tooling for the manufacture of Ébauche 01.

Côtes de Genève are made in the heart of Switzerland, in La Chaux-de-Fonds, a town famous for its historic watchmaking houses and the century-old supplier workshops it hosts.

The blued screws have been selected for their quality but also for their guarantee of origin. Indeed, they come from a Swiss company, located in the village of Le Sentier in the heart of the Vallée de Joux, which supplies the greatest watch brands.

The rubies set in Ébauche 01 were chosen by Luc Monnet and come from his own stock. They were purchased from a manufacturer located in Le Locle, Switzerland. The purchase dates back to the 90’s and never been used, so the jewels are new and come from a carefully kept stock.

In a world where the machine has usurped man’s know-how, we have chosen to take a different path: that of manual finishing and assembly in France.

While creating Ébauche 01, our path crossed with Luc Monnet, an exceptional creative watchmaker. He worked in the greatest watchmaking houses and then chose to set up his workshop in the center of France. Adept of unique creations, he works for the greatest watch brands, bringing them solutions to mechanical problems encountered, such as reproducing a part that could not be found or creating a prototype of a totally innovative movement.

Luc Monnet is also a talented watchmaker recognized in his country. In 2015, he created a pocket watch with satellite time display and became “Best Artisan of France -Meilleur Ouvrier de France” in the watchmaking category.

It is with great humanity, as well as a true willingness to transmit his precious experience and share his passion, that Luc Monnet accompanied us in this project. He patiently trained us, like apprentices, so that we would be able to carry out the finishing touches ourselves.

The finishes (brushing of the sides, satin-finishing, polished bevels, polished inner chamfers), as well as the final assembly are hand-made by us, piece by piece, in our workshop located in the South of France. Only one person is involved in the finishing, screw and jewel assembly of each Ébauce 01.

As a result, the production of this unique timepiece is necessarily limited.

We also wanted to further explore the notion of INDICE in the box accompanying Ébauche 01. It was designed as a real secret box. One part of the box is completely removable, making it possible to conceal precious objects or other watchmaking clues such as watch straps.

Glass tubes comes with our bracelet. In the past, they were used by watchmakers to store fragile and essential mechanical parts, such as hands for example.

We have chosen a very special glass tube, in which we have included a blued screw and an extra synthetic ruby to let you discover the pleasure of holding them in the palm of your hand.

You will be able to admire them in complete freedom, appreciating their size and quality.